OPEN SOURCE TRASH EATING ROBOTS

*SOME ASSEMBLY REQUIRED

The Trash Printer is a design for an open-source 3D printer that can print useful objects directly from recycled plastic flakes instead of using filament. This makes it easier to print with post-consumer trash, and makes the process more tolerant of impurities in the material. It is intended to be disruptively easy to build, and costs around $500 in parts. This website exists to teach you how to build one with your friends so that you can turn the trash around you into new and useful objects.

HOW IT WORKS

SORT

Plastic waste is sorted by type and washed to remove any food and labeling. The Trash Printer prints with #5 Polypropylene, #2 HDPE, #4 LDPE, and probably others too!

SHRED

The sorted plastic is shredded using the Precious Plastic open source plastic shredder. A mesh screen ensures uniform particle size for easy handling.

The shredded flakes are loaded into the hopper of the printer, and a screw feeds it downwards through a heated barrel and out the nozzle, like a glue gun.

REPEAT

Parts that are no longer needed can be mixed with new material and reprinted in a near-infinite loop. The parts it makes are large, light, strong, and flexible.

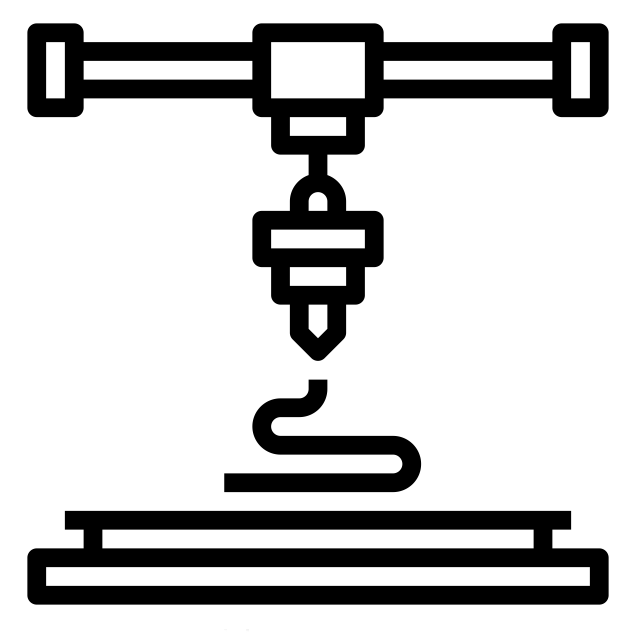

3D printing with recycled plastic may seem kind of inevitable, but making hundreds of feet of micron-perfection filament out of real-world post-consumer waste is a pretty tricky thing to do, and the common recyclable plastics all have properties that make them more difficult to print with than PLA or ABS. Instead of trying to make a filament that works in existing desktop 3D printers to make small, detailed objects, the Trash Printer skips the filament entirely by just strapping the filament extruder onto a CNC router gantry. This approach enables the printing of large, strong, flexible, but relatively low resolution objects directly from shredded plastic flakes with minimal additional processing.

HOW TO BUILD ONE

This project is intended to be replicated. You are not only allowed to copy this information freely and without permission, you are encouraged to do so and this documentation is intended to make that process as easy as possible, so that people anywhere can use it to turn the plastic trash around them into objects that are useful and valuable in their communities.

You can find the most recent documentation on Here

And you can support the development of this project at Patreon.com/DisruptivelyUseful

Here’s what you will need:

TOOLS:

A CNC Gantry

The Gantry is the robot that moves the extruder around. We’re using the Mostly Open Source “Mostly Printable CNC” gantry, but any CNC router gantry with at least some Z travel should work.

Laser Cutter or Router

The extruder uses laser-cut wooden spacers to hold the parts in place. Wood is actually the best material for this, so you will need the ability to accurately cut parts out of plywood sheets.

Power Drill + Bits

You will need a cordless electric power drill, 3/8″ drill bit, 1/8″ drill bit, and an 8-32 tap set. This is for modifying the hot end to work with the larger nozzle the printer uses

Soldering Tools

You will need to fabricate your own custom cables for your printer, so you will need a soldering iron and wire stripper/cutters. A set of helping hands doesn’t hurt either.

PARTS

MPCNC

Or comparable CNC gantry with stepper motors and some Z

Wood Auger

7 1/2″ long by 9/16″ diameter.

4:1 NEMA 23 Stepper

Geared to get enough torque to extrude smoothly

3" PVC Wye

ABS works too

Shaft Coupler

10mm to 12mm

4" Stainless Pipe

4″ long by 1/2″ wide NPT pipe thread

Barrel Adapter

1/2” FPT to 1/4” FPT Brass Adapter

Hose Barb Nozzle

1/4” MPT x 1/4” Brass Hose Barb

1/2” Black Steel Pipe Flange

Or comparable CNC gantry with stepper motors and some Z

Aluminum Heater Block

7 1/2″ long by 9/16″ diameter.

Cartridge Heater

24VDC

Band Heater

150W 120VAC Band Heater

Solid State Relay

Or “PowerTail” style relay.

(2) Carriage Bolts

8″ long 1/4″ x 20 thread

(2) Hex Flange Nuts

(2) Thermistors

7 1/2″ long by 9/16″ diameter.

Wooden Spacers

Laser cut, CNC routed, or cut by hand

Power Connectors

150W 120VAC Band Heater

LICENSE

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Creative Commons

All content on this website is open source and licensed under Creative Commons with the following guidelines and requests. Please steal this information.

Attribution

I have attempted to give credit where credit is due to the other people who contributed to this work, and would appreciate it if you would do the same!

Share Alike

This project is built upon thousands of hours of other people’s work. Please pay that work forward by making your work open as well

CC-Zero

CC0 is a legal tool for waiving as many rights as legally possible. This information is intended to be free to use for whatever purposes you choose.